Quality & Safety at a Fraction of the Cost

EVO One is a state-of-the-art, dual-retort tissue processor designed for operational cost savings with unique versatility and efficiency. It offers unmatched flexibility to streamline workflows and optimize operator time. Featuring a unique reagent management system that simplifies reagent handling while prioritizing the utmost safety for operators and specimens alike. EVO One not only slashes operational costs but also dramatically reduces turnaround times—empowering your lab to achieve more with less.

-

Optimized Dual Retort Processing

Optimized Dual Retort Processing -

Enhanced Safety for Operators & Specimens

-

Smart Reagent Management

-

Intuitive User Interface

-

Enhanced Traceability

Request a quote

Optimized Dual Retort Processing

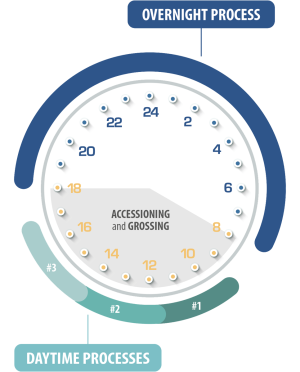

With its versatile dual-run and automated modes, EVO One empowers labs to process urgent specimens across multiple daytime cycles with ease, delivering results without delay.

A dedicated wax retort revolutionizes efficiency by removing the need for time-intensive cleaning cycles in between runs. EVO One eliminates the repetitive pumping of wax in and out, saving valuable time and reducing maintenance demands. EVO One delivers exceptional results even for challenging large or fatty specimens.

Parallel Processing

Traditional Tissue Processing Workflow

EVO One Tissue Processing Workflow

Safer for Operators and Specimens

EVO One prioritizes safety at every step, delivering a secure environment for operators while providing unparalleled protection for specimens by eliminating Xylene: harshness to the tissue and harmful for operators.

By seamlessly incorporating two separate manifolds—one dedicated to water-based solutions and another to alcohol-based reagents—EVO One minimizes the risks of cross-contamination and carry-over, extending reagent longevity and safeguarding specimen integrity.

Engineered for versatility, EVO One excels in processing all tissue types with precision. Its rigorously validated protocols guarantee superior morphological and molecular preservation, trusted and implemented in hundreds of pathology labs worldwide for consistent, high-quality outcomes.

Smart Reagent Management

The EVO One system utilizes standard 5-liter or 1-gallon commercial tanks, eliminating the need for reagent decanting. This design ensures quick, hassle-free tank replacements, minimizing downtime and preventing spills or cleanup.

Dedicated connectors and optional barcode scanning for reagents guarantee an error-free, fully traceable process, enhancing operational efficiency and reliability.

EVO One significantly reduces reagent consumption and supports eco-friendly practices by accommodating sustainable alternatives whilst prioritizing operator safety and environmental responsibility.

Intuitive User Interface

A smart, icon-driven software guides the user through the entire protocol, enabling operators to effortlessly navigate and select the correct processing parameters.

For routine operations, favorite protocols are quickly selected and started, allowing the user to save time during protocol configuration and enhancing the efficiency of the operational workflow.

All parameters, reagents, and cassette information is collected for complete documentation. An automatic pre-start check ensures the proper status of the system prior to processing.

Request a Virtual Demo

MileWATCH

24/7 Tracking and Monitoring

Track, monitor and manage specimens throughout their journey.

Discover More

Milestone Tissue Processors: Trusted by Leading Pathology Labs

Why Colorado Skin Pathology Trusts EVO

Colorado Skin Pathology shares how the EVO tissue processor has improved their laboratory workflow and results. They explain how EVO consistently delivers high-quality processing for even the most challenging specimens, while saving technician time through simple reagent management and xylene-free protocols.

Watch how EVO helps laboratories provide reliable turnaround, safer working conditions, and the highest diagnostic standards.

TIAGA Pathology Shares Their Success Story

TIAGA Pathology shares how their lab benefits from Milestone’s processing solutions. Inside the video, they discuss how performance consistency, streamlined workflows, and safer, xylene-free protocols impact daily operations. See firsthand how their team achieves faster turnaround, better quality, and reduced rework.

Watch now to learn how TIAGA makes their lab more efficient with Milestone.